SRG METALCRAFTS (INDIA) PVT. LTD.

"Honesty makes the brand; quality wins the market"

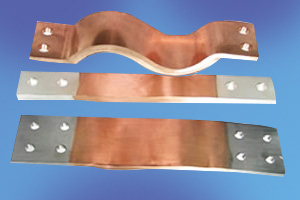

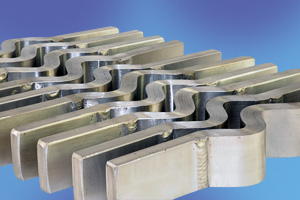

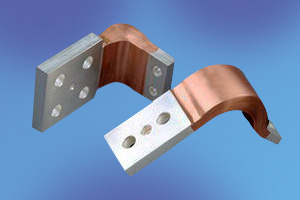

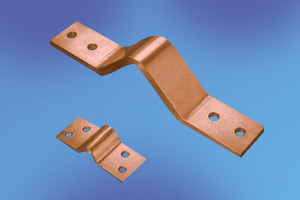

For a long time the concept of copper flexible was just stacking together bunches of foils and connecting the same. Further, riveting at the ends was started and was further improved by soldering/brazing/welding. But the loss of energy was never considered/assessed. Later on, as the cost of energy increased tremendously, the technique of hot pressed electro fusion process for Copper Flexible & tig welding process for aluminum flexible was put in use which is the latest trend and resulting into substantial savings in energy cost. SRG is using the same technique.

SPECIFICATIONS